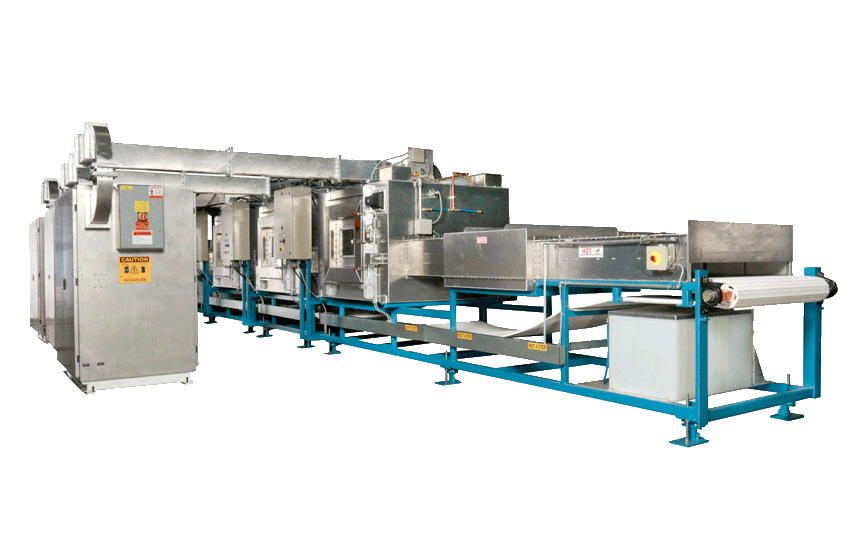

Conveyorized Modular Industrial Microwave Power Systems

Production Engineering’s Conveyorized Modular Industrial Microwave Systems are built in a large variety of shapes and sizes according to the requirements of the continuous heating process. Each module can apply up to 100kW of power to the product being heated and operates at 915 MHz. Based on the power requirements, two or more modules can be installed on the same conveyor. To assure uniform heat distribution in a large variety of load configurations, the multimode cavity is provided with a Waveguide Splitter with dual microwave feed points and Mode Stirrers.

The product being heated is carried through the oven by a unique conveyor belt. The belt material and configuration are selected based on the nature of the product being heated. Each end of the conveyor is provided with a special vestibule to suppress any microwave energy leakage. Air intake and exhaust ports are provided for circulating air to be used in cases where vapors or fumes are developed during the heating process.

COMMON USES:

- Drying or curing

APPLICATIONS:

Ceramics • Catalysts • Vulcanizing • Composites • Bulk fibrous components • Sand cores • General drying & heating of electrically non-conductive materials • Research & development

CONVEYORIZED MODULAR INDUSTRIAL MICROWAVE POWER SYSTEMS FEATURES

- An Allen Bradley PLC with Allen Bradley HMI provides automatic operation

- Programmable to operate at maximum efficiency

- Recording and Storage of up to 32 Operating Parameter recipes

- Auxiliary Hot Air System uses electric heat to preheat the air circulating throughout the cavities

- On screen diagnostics, help screens and alarm messaging to assist with troubleshooting

- Designed for ease of inspection, installation, and maintenance

THERMEX CONVEYORIZED MODULAR INDUSTRIAL MICROWAVE POWER SYSTEMS

On screen calibration of all analog signals include:

- Reflected Power

- Filament Current

- Anode Current

- Magnet Current

- Anode Voltage

- Output Power