Custom

Maximize Productivity

We supply custom-built resistance and GMAW welding machines. Our design team is experienced and capable of producing a straight-forward engineering concept that results in the optimal machine system to meet customer objectives. We listen first, then ponder, then propose a machine solution. You will be successful with our machines!

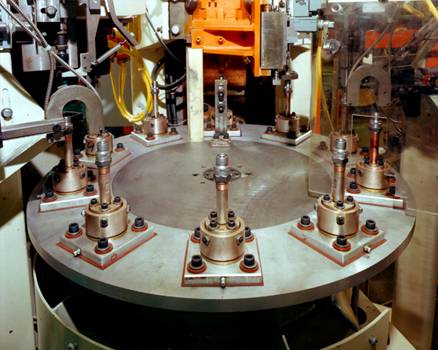

Dial Index Machines We have experience supplying automatic dial index welding machines with up to 16 Stations. Parts can be manually or automatically loaded / unloaded based on production demands.

Special Multi-Spot Machines We have supplied many special application multi-head spot welding machines for the office furniture, 2nd tier automotive, aerospace, electronic components, battery, and appliance industries. Depending on production requirements, these machines can be loaded by robot or by an operator.

Conventional Seam Welders

Special Robot loaded Pedestal Welders Systems can be controlled via Device Net and tooled with a shuttling fixture. This allows for 2 (or more) different style or size fasteners to be welded on the same machine. Interchangeable tooling plates can accommodate a family of different production parts.

Special Fast-Follow-Up Press Welders Press welders can be designed with a specially designed die-spring package to allow for immediate response of the upper electrode during the welding process. A highly accurate displacement sensor can be installed to verify satisfactory welds are made.

Robotic GMAW Weld Cells We have experience supplying arc welding cells that use various work holding fixtures. These systems consist of 1-5 stations, and are designed to get maximum up time from the robot and the welder. Depending on your application, the robot can manipulate the part through various fixed weld stations, or manipulate the weld head around a fixtured part assembly.