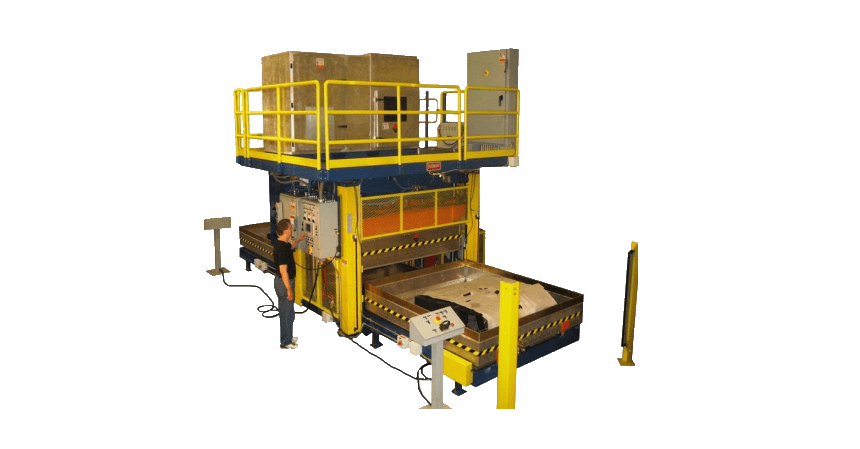

Automotive Carpet Pad RF Welding System

Production Engineering’s state-of-the-art, computer controlled Automotive Carpet Pad RF Welding System is a heavy duty, industrial grade product line designed and built in accordance with the rigorous performance requirements of today’s automotive industry. These Automotive Carpet Welders can perform multiple pad seals (heel, toe and scuff) in a three dimensional configuration over a range of pad sizes on a 24 hour/7 day a week operation basis. The RF Carpet Welder incorporate the latest in both PLC and radio frequency technology by providing loading and sequential sealing of all pads, without the need to reload the carpet. The RF output circuit is designed to provide maximum flexibility to accommodate a large variety of carpet configurations.

COMMON USES:

Automotive industrial manufacturing

APPLICATIONS:

Welding heel, toe and scuff pads to automotive carpet

AUTOMOTIVE CARPET PAD RF WELDER FEATURES

- An Allen Bradley PLC automatically tunes and monitors process parameters during each welding cycle

- An SCR controller directs plate voltage providing greater flexibility

- Maximum output power adjustable up to 40kW

- Two (2) opposing shuttles for maximum productivity

- Heavy duty four (4) post style construction

- Industrial grade pneumatic press with precision guide system

- Designed to provide up to ten (10) tons of force on each load

- Independently operated, double shuttle system powered by electric motor

- Two (2) operator stations

- Four (4) quadrant control acceleration, deceleration and braking

- Indexes into bonding area within five (5) to six (6) seconds